6 Jointer Pointers

These simple techniques will ensure that your jointer really earns its keep. You’ll not only appreciate this workshop workhorse more, you’ll get better results and great production, too.

:max_bytes(150000):strip_icc():format(webp)/375_1_2-dd5ac7c7818a4ef8b293a569fcc2095b.jpg)

Steps 1, 2 & 3

These simple techniques will ensure that your jointer really earns its keep. You’ll not only appreciate this workshop workhorse more, you’ll get better results and great production, too.

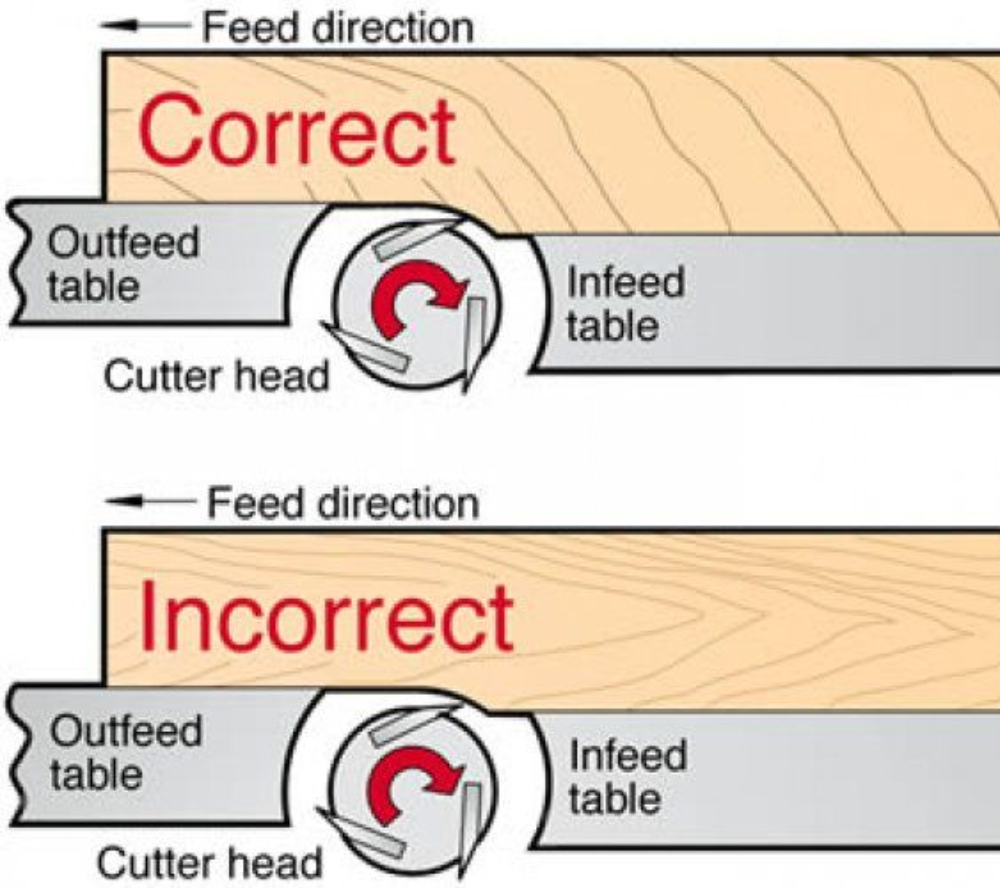

1. Always joint downhill. When edge-jointing, you have to read the grain for the correct direction to feed the stock to avoid tear-out. As shown in Drawing A, feeding stock with the grain running “downhill” from the outfeed table and away from the knive’s rotation produces the best results. If grain runs in several directions, position the board so that most of it runs in that direction. End grain generally should not be jointed because the knives will shatter any unsupported portion of it.

2. A quick adjust for outfeed. A misaligned outfeed table results in less than perfect cuts. Set too high, you get a concave surface. Too low, and the cut will be heavier at the back end of the stock. But it doesn’t take much effort to set the outfeed table to match the height of the knives for a perfect cut.

As shown in Drawing B, first lower the outfeed table slightly, next turn on the jointer. Set the infeed table for a light cut, then slowly feed a piece of scrapstock on edge across the knives. Cut into the stock a few inches until about 1″ projects over the outfeed table. Now, shut off the machine. Raise the outfeed table until it touches the bottom of the stock’s jointed portion, then lock it in place. To check the new setting, finish jointing the edge and make a second pass, pausing 2″ into the cut to see if the outfeed table now fully supports the wood.

3. Joint the face first. To get a jointed edge that’s square to the face of a board, you should joint the face first. Then, with the newly jointed face against the fence (with the grain running downhill), joint one edge square with it. This gives you one flat surface as a base for further milling and a true edge for ripping.

:max_bytes(150000):strip_icc():format(webp)/375_1_3-cfd3ac925d5147c7bb83e03bc76ba611.jpg)

:max_bytes(150000):strip_icc():format(webp)/375_2_2-62f5664a433f440bbeb8f378b8a3f6d2.jpg)

:max_bytes(150000):strip_icc():format(webp)/375_2_3-ea5874bd7e6d4989bcbcc996053e5a41.jpg)